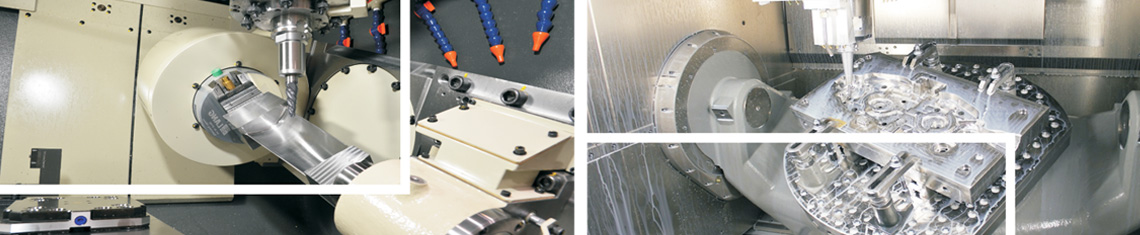

Corner Radius Endmill improve productivity and reduce costs. A sharp corner of an end mill is its weakest point. The corner radius design strengthens the end mill by reducing chipping and providing longer tool life. In mold applications where ball end mills have traditionally been used, a corner radius end mill will remove more material faster, improving productivity. Saves the cost of grinding a radius using conventional end mills.

Standard

| Item Code |

Cutting Dia. |

Shank Dia. |

Radius |

Flute length |

Over all length |

| SF4CR030 R0.5 |

3 |

3 |

0.5 |

10 |

51 |

| SF4CR040 R0.5 |

4 |

4 |

0.5 |

14 |

51 |

| SF4CR040 R1.0 |

4 |

4 |

1 |

14 |

51 |

| SF4CR050 R0.5 |

5 |

5 |

0.5 |

16 |

51 |

| SF4CR050 R1.0 |

5 |

5 |

1 |

16 |

51 |

| SF4CR060 R0.5 |

6 |

6 |

0.5 |

19 |

63 |

| SF4CR060 R1.0 |

6 |

6 |

1 |

19 |

63 |

| SF4CR060 R1.5 |

6 |

6 |

1.5 |

19 |

63 |

| SF4CR080 R0.5 |

8 |

8 |

0.5 |

21 |

63 |

| SF4CR080 R1.0 |

8 |

8 |

1 |

21 |

63 |

| SF4CR080 R1.5 |

8 |

8 |

1.5 |

21 |

63 |

| SF4CR080 R2.0 |

8 |

8 |

2 |

21 |

63 |

| SF4CR100 R0.5 |

10 |

10 |

0.5 |

25 |

70 |

| SF4CR100 R1.0 |

10 |

10 |

1 |

25 |

70 |

| SF4CR100 R1.5 |

10 |

10 |

1.5 |

25 |

70 |

| SF4CR100 R2.0 |

10 |

10 |

2 |

25 |

70 |

| SF4CR100 R2.5 |

10 |

10 |

2.5 |

25 |

70 |

| SF4CR120 R1.0 |

12 |

12 |

1 |

25 |

75 |

| SF4CR120 R1.5 |

12 |

12 |

1.5 |

25 |

75 |

| SF4CR120 R2.0 |

12 |

12 |

2 |

25 |

75 |

| SF4CR120 R3.0 |

12 |

12 |

3 |

25 |

75 |

| SF4CR160 R1.0 |

16 |

16 |

1 |

35 |

89 |

| SF4CR160 R2.0 |

16 |

16 |

2 |

35 |

89 |

| SF4CR160 R3.0 |

16 |

16 |

3 |

35 |

89 |

| SF4CR160 R4.0 |

16 |

16 |

4 |

35 |

89 |

| SF4CR200 R1.0 |

20 |

20 |

1 |

40 |

101 |

| SF4CR200 R2.0 |

20 |

20 |

2 |

40 |

101 |

| SF4CR200 R3.0 |

20 |

20 |

3 |

40 |

101 |

| SF4CR200 R4.0 |

20 |

20 |

4 |

40 |

101 |

Endmill - 6 Flute Standard

| Item Code |

Cutting Dia. |

Shank Dia. |

Flute length |

Over all length |

| SF6EM060 |

6 |

6 |

19 |

63 |

| SF6EM080 |

8 |

8 |

21 |

63 |

| SF6EM100 |

10 |

10 |

22 |

70 |

| SF6EM120 |

12 |

12 |

25 |

75 |

| SF6EM140 |

14 |

14 |

30 |

76 |

| SF6EM160 |

16 |

16 |

32 |

76 |

| SF6EM180 |

18 |

18 |

35 |

100 |

| SF6EM200 |

20 |

20 |

40 |

100 |